―To meet customers’ needs for increased productivity and efficiency, we are introducing the most powerful AC electric lift truck Toyota has ever built,‖ said Brett Wood, president of TMHU.

With the 8-Series 4-wheel AC-powered lift trucks, Toyota offers our customers improved performance speedsincluding up to 21 percent faster travel speeds over the previous model. Toyota’s New 8-Series 4-Wheel Electric Lift Truck Raises Industry Standards.

AC Power System with Revved- Up Travel and Lift Speeds

Toyota was the first major lift truck supplier to bring AC technology to the North American market. Taking this acclaimed technological advancement to new levels, Toyota’s lift truck offerings now include a 4-wheel AC-powered lift truck with the distinct performance advantages of Toyota-designed, motors and controllers. The AC-powered system is comprised of a series of subsystems—each of which either conserves or regenerates power to maximize operational productivity between battery charges. The motor features a ―power keep‖ function, which is designed to compensate for battery depletion and corresponding loss of performance, allowing for longer run times and more consistent power output throughout the length of each battery charge cycle. In addition, energy is continually recovered through three forms of regenerative braking, coast control, plug braking and foot braking extending run times significantly and prolonging brake component life.

Reduced Maintenance to Improve Customers’ Bottom Line

Toyota’s virtually maintenance-free AC power system contains no motor brushes, springs, commutator or wearable parts to service and replace, resulting in fewer, quicker and less expensive maintenance and operational costs. The lift truck’s AC-powered drive system and AC-powered hydraulic system boost travel and lift speeds. Also, by controlling the on-demand, full hydrostatic power steering through the AC hydraulic motor system, there is one less motor to service and maintain.

This notable increase in AC-powered performance, combined with a reduction in down time for maintenance, means significant enhancements in productivity and efficiency for customers.

Enhanced Visibility

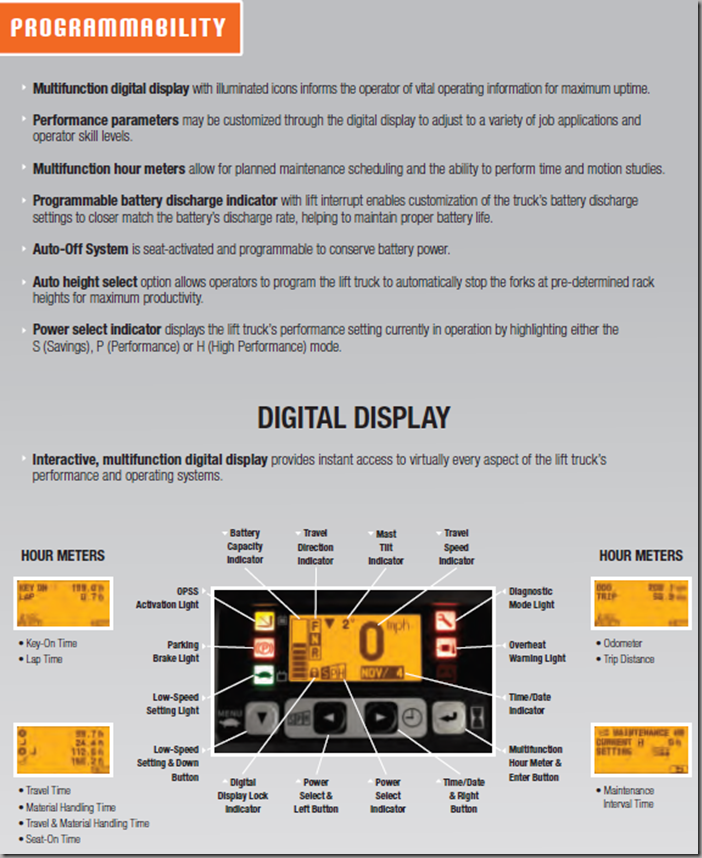

A number of operator visibility enhancing features were integrated into the new

4-wheel electric AC lift trucks including angled tie-bars on both the overhead guard and load backrest extension along with lowered free-lift cylinders on both the 3-stage and

4-stage masts. The 8-Series Multifunction Digital Display was also integrated into the front cowl to give the operator an uncluttered forward view toward the load and operating environment, and the fork color was changed to orange in order to help clearly define the position of the fork tips.

Additional Lift Truck Operability Enhancements

A Momentary Hold and Controlled Descent feature is now standard and maximizes lift truck control by regulating rolling speed when the accelerator pedal is released on a grade. It also allows the lift truck to be started on an inclined surface without rolling backward.

Also, a Shock Sensor option, integrated into the multifunction digital display, enables end users to monitor lift truck damage or fleet abuse. When an impact is detected that exceeds a pre-set level it warns the operator by displaying a highlighted ―Shock Sensor Alarm icon on the display and sounding a buzzer. At the same time the controller records the date and time of the event to be later retrieved by the warehouse manager through the digital display. If the lift truck is equipped with the Keyless Entry System option the controller will also record the PIN of the operator that was driving the unit at the time of truck impact. This will facilitate determining the operator responsible for the damage caused to the equipment. This system cannot be deactivated even if the operator tries to reset it by either turning the key, off and on again, or by disconnecting

and reconnecting the battery connector. Only the warehouse manager with the appropriate password can reset the system. Additionally, for maximum productivity and to minimize product damage, an Auto Height Select option is available to allow warehouse managers to program the lift truck to automatically stop the forks up to three pre-determined rack heights.

Call now to place orders or for additional info.

Southern States Toyotalift and Florida Lift Systems

800.226.2345 | info@floridalift.com

115 S. 78th St, Tampa, FL 33619

wow....useful tips for me because I'm not so able to do make up! :) you're so precious! Lovely Read!

ReplyDeleteToyota Electric Forklift